Hydraulic Flange Spreaders

Hydraulic Flange Spreaders Specification

- Model No

- HS-15 (example)

- Automatic Grade

- Manual

- Material

- High Strength Alloy Steel

- Usage & Applications

- Separation of flange joints in pipeline maintenance, installation, testing, and repair

- Size

- Standard and Customized Sizes

- Capacity

- 4 - 15 Tons

- Type

- Hydraulic Flange Spreader

- Grade

- Industrial Grade

- Dimension (L*W*H)

- 450 x 250 x 130 mm (approx.)

- Noise Level

- Low

- Power

- Manual Hydraulic

- Voltage

- N/A (manual operation)

- Weight

- 8 - 15 kg

- Operation Mode

- Hand pump driven

- Spreading Force

- Up to 150 kN (depending on model)

- Max Spreading Distance

- 81 mm (varies by model)

- Color

- Yellow/Black (standard)

- Corrosion Resistance

- Yes

- Oil Pressure

- 700 bar (max)

- Safety Feature

- Integrated safety lock system

- Min Access Gap

- 6 mm - 10 mm (varies by model)

Hydraulic Flange Spreaders Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1 , , Piece Per Day

- Delivery Time

- 7-50 Days

About Hydraulic Flange Spreaders

Specification

- Max. Flange Thickness (mm) : 2x92 mm

- Stud Size (mm) : 19-41 mm

- Output Force (ton) : 5-10Ton

- Spread : 70-216 mm

Features :-

- Light Weight, Ergono Mic design for ease of use.

- Adjustable Jaw Widths from 70 to 216 mm for a wide range of Applications.

- S/A, Spring Return

- Operated by Hydraulic Pump with rated Pressure of 700 Bar.

Highly Efficient Flange Separation

Designed for professionals, our Hydraulic Flange Spreaders provide reliable and precise separation of flange joints. The high spreading power (up to 150 kN) ensures optimal performance during pipeline maintenance and repair. Thanks to a slim access gap and sturdy construction, these tools are essential for challenging industrial environments.

Safe and Durable Construction

Each spreader is manufactured from high-strength alloy steel and built for industrial-grade durability. The corrosion-resistant finish and integrated safety lock system further enhance operator safety. Manual hydraulic hand pump operation allows for controlled movement in demanding work settings.

Versatile Applications Across Industries

Our hydraulic flange spreaders are ideal for use in pipeline maintenance, installation, and testing. Suitable for oil and gas, chemical, and water treatment facilities, these tools are supplied to distributors, service providers, and end-users throughout India. Customizable sizes ensure compatibility with varied tasks.

FAQs of Hydraulic Flange Spreaders:

Q: How does a hydraulic flange spreader work during pipeline maintenance?

A: A hydraulic flange spreader uses manual hand pump power to generate up to 150 kN of spreading force, allowing operators to safely and efficiently separate flange joints. The integrated safety lock ensures secure operation, making it essential for pipe maintenance, installation, and repair.Q: What are the typical applications of these flange spreaders?

A: These hydraulic flange spreaders are typically used for separating flange joints in industrial pipelines during maintenance, installation, and pressure testing. They are valuable for oil, gas, chemical, and water industries across India.Q: When should I use a hydraulic flange spreader instead of a manual tool?

A: A hydraulic flange spreader should be used when greater spreading force, controlled motion, and enhanced safety are required, especially in industrial-grade applications where manual tools may not provide sufficient power or safety features.Q: Where can I use the hydraulic flange spreader safely?

A: These spreaders are suitable for on-site pipeline work in facilities like oil refineries, chemical plants, and water treatment stations throughout India. The compact size and corrosion resistance make them ideal for diverse and often demanding work environments.Q: What is the process for operating the hydraulic flange spreader?

A: To operate, insert the tool into the flange access gap, connect the manual pump, and gradually apply hydraulic pressure. The integrated safety lock system ensures the flanges remain securely separated during the process, minimizing risk to the operator.Q: How do the safety features benefit operators?

A: The built-in safety lock system minimizes accidental closures and ensures stable flange separation during maintenance work, greatly reducing the risk of injury and enhancing operational confidence for the user.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bolting Category

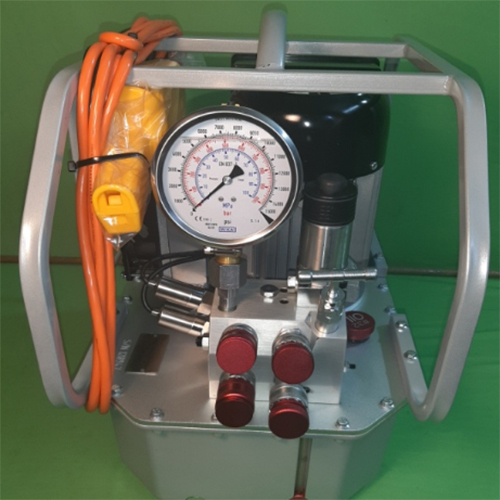

Electric Pump For Torque Wrench

Price Range 300000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Power : 1.5 kW

Type : Other, Electric Pump For Torque Wrench

Model No : EPTW700

Automatic Grade : SemiAutomatic

Hydraulic Nut Splitters

Price Range 70000.00 - 150000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Power : Hydraulic (50700 bar operating range)

Type : Other, Hydraulic Nut Splitter

Model No : HNSSeries

Automatic Grade : Manual

Digital Electric Torque Wrench

Price Range 300000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 500W

Type : Other, Digital Electric Torque Wrench

Model No : SDBT2000

Automatic Grade : Automatic

Hydraulic Wedge Spreader

Price Range 50000.00 - 100000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Power : Hydraulic

Type : Other, Hydraulic Wedge Spreader

Model No : WS10

Automatic Grade : Manual

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese