Hexagonal Cassette Torque Wrenchs

Hexagonal Cassette Torque Wrenchs Specification

- Size

- Suitable for nuts and bolts across multiple widths

- Automatic Grade

- Manual/Hydraulic

- Usage & Applications

- Heavy-duty bolting applications, Oil & Gas, Construction, Industrial fittings, Power plants

- Capacity

- From 164 Nm up to 72,700 Nm

- Model No

- Various (refer to manufacturer for specifics)

- Material

- High Strength Steel/Alloy

- Type

- Hexagonal Cassette Torque Wrench

- Grade

- Industrial

- Dimension (L*W*H)

- Various standard sizes

- Noise Level

- Low

- Power

- Hydraulic (External Pump required)

- Weight

- Depends on model, typically 2.2 kg and above

- Rotation Angle

- 360° x 180° multi-position adjustment

- Operating Temperature Range

- -20°C to +50°C

- Surface Treatment

- Corrosion resistant anodized finish

- Accuracy

- +/- 3%

- Maximum Torque Output

- 72,700 Nm

- Interchangeable Cassettes

- Yes, for different nut sizes

- Drive Mechanism

- Hydraulic driven with hexagonal cassette

- Max Working Pressure

- 700 bar

- Minimum Torque Output

- 164 Nm

- Safety Features

- Over-pressure safety valve, secure lock system

Hexagonal Cassette Torque Wrenchs Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 1 , , Piece Per Day

- Delivery Time

- 7-50 Days

About Hexagonal Cassette Torque Wrenchs

Specification

- Torque Range (NM) : 223-44593

- Hex Range : 175mm A/F

- Maximum Pressure : 700 bar

Features :-

- 5 Models with the range from 232-44593 N.m

- 360*180 degree swivel & 360*360 degree swivel allow the wrench free to operation with no space limitation.

- More accuracy and easier when the wrench direct operate on the nuts.

- Compact design with longer arm fully advances the reliability.

- Compact design with the raw material of advanced aluminum-titanium alloy, high intense,

- The new locking coupler ensures the oil keep free access.

Maximum Performance and Flexibility

This torque wrench stands out for its exceptionally wide torque range, handling both light and heavy-duty bolting tasks with ease. The multi-position adjustment feature and hydraulic drive mechanism enable efficient operation in restricted or complex spaces, enhancing its usefulness across various industries.

Built for Safety and Durability

Safety remains paramount, with the wrench equipped with an over-pressure safety valve and secure lock system to prevent accidents during use. The corrosion-resistant anodized finish and high-strength steel alloy construction ensure long-lasting durability, even in harsh environmental conditions.

Efficient Installation and Maintenance

Changing out cassettes for different nut sizes is quick and straightforward, making this tool not only efficient for fast-paced projects but also cost-effective. Routine maintenance is simplified thanks to its robust design and low noise levels, supporting safe and comfortable operations.

FAQs of Hexagonal Cassette Torque Wrenchs:

Q: How does the interchangeable cassette system work in this torque wrench?

A: The hexagonal cassette torque wrench features a quick-change mechanism that allows users to swap cassettes easily to fit different nut sizes. This design increases versatility and reduces downtime for various bolting applications.Q: What safety protections are included in the torque wrench?

A: The wrench is equipped with an over-pressure safety valve and a secure lock system to protect users from accidental hydraulic over-pressurization and unintended cassette release, ensuring safer operation in industrial environments.Q: Where can the hexagonal cassette torque wrench be used?

A: It is suitable for use in oil & gas installations, construction sites, heavy machinery maintenance, industrial fittings, and power plantsessentially any setting requiring precise heavy-duty bolting.Q: What is the process for setting torque output on this wrench?

A: Operators use an external hydraulic pump to set and achieve the desired torque. The wrenchs accuracy of 3% ensures each setting delivers consistent results, and multi-position adjustments make accessing tight spaces straightforward.Q: When should cassette replacement or maintenance occur?

A: Cassettes should be replaced or maintained whenever there are signs of wear or if a different nut size is required for the task. Routine inspections help keep performance at optimal levels and prolong tool longevity.Q: What are the main benefits of using this tool for industrial bolting?

A: Benefits include high torque capability, precise accuracy, quick adaptability to multiple nut sizes, corrosion resistance, operator safety, and suitability for intense bolting tasksmaking it indispensable for critical applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bolting Category

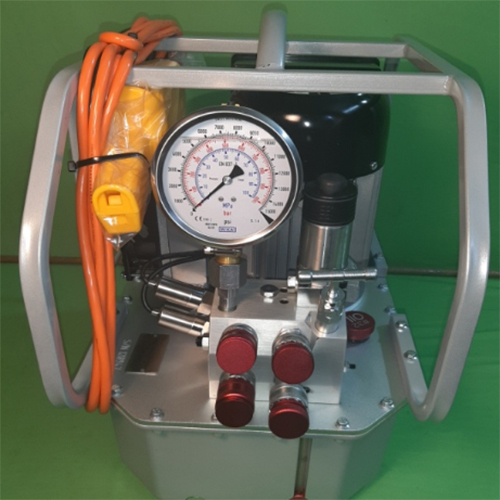

Electric Pump For Torque Wrench

Price Range 300000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Power : 1.5 kW

Capacity : 5 to 7 Litres

Material : High Strength Alloy Steel & Aluminum

Model No : EPTW700

Pneumatic Impact Wrench

Price Range 8000.00 - 60000.00 INR / Number

Minimum Order Quantity : 1 , , Number

Power : 700 Nm Max Torque

Capacity : 700 Nm

Material : Aluminium Alloy + Steel

Model No : CP818

Hydraulic Nut Splitters

Price Range 70000.00 - 150000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Power : Hydraulic (50700 bar operating range)

Capacity : Singleacting, suitable for regular duty

Material : High grade alloy steel cutter and body

Model No : HNSSeries

Digital Electric Torque Wrench

Price Range 300000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 500W

Capacity : 1002000 Nm

Material : Alloy Steel

Model No : SDBT2000

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese